Advantges of Our Hoses

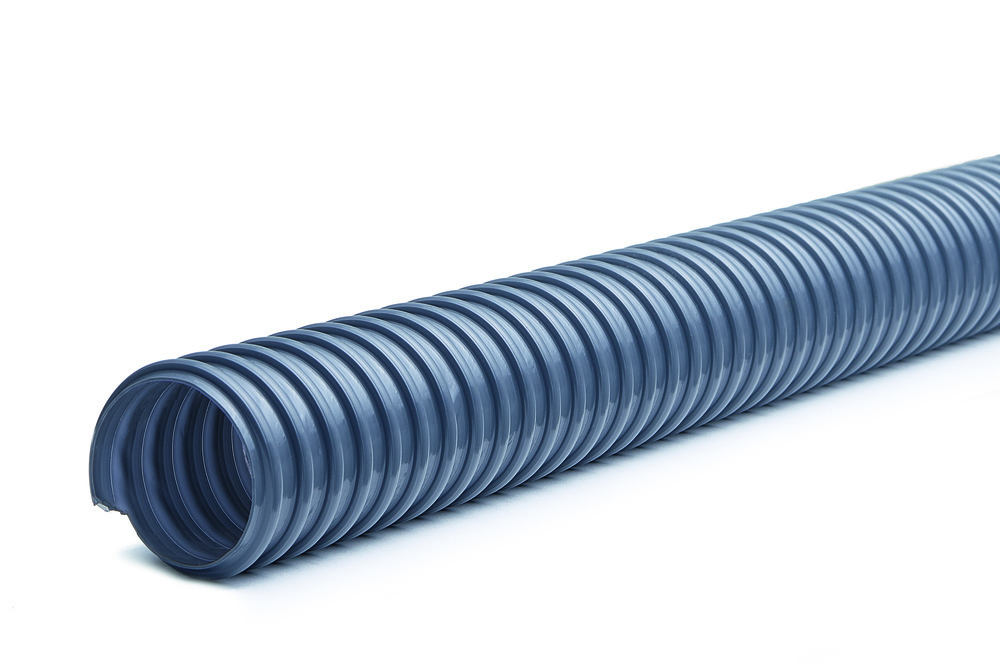

APD Schlauchtechnik GmbH offers first-class hoses for all areas of mechanical and plant engineering: from hydraulic systems and cooling systems to conveyor technology, rejection systems and chemical processing plants – there are countless areas in which hoses are used. Our solutions are reliable and tailored to your individual requirements.

Discover All Products

Our Top-Applications

Hoses in machinery and plant engineering are indispensable for hydraulic and pneumatic systems, cooling and lubrication systems, and conveyor technology. They enable the safe transport of hydraulic fluids, compressed air, coolants and lubricants. They also play a crucial role in extraction and vacuum systems for removing exhaust gases and contaminants. Our hoses are tailored to your specific requirements.

Hydraulic & Pneumatic Systems

Hydraulic systems use hoses to transfer hydraulic fluids that exert pressure on machine components, thereby controlling movements and functions. Pneumatic systems use hoses to transport compressed air, which is required for the operation of machine drives and valves. Both systems are central to control and functionality in mechanical and plant engineering.

Learn more

Cooling & Lubricant Systems

Cooling systems use hoses to transport coolants and thus protect machine components from overheating. Lubrication systems use hoses to distribute lubricants, reducing friction and wear on moving parts. Both systems are essential for the longevity and efficiency of machines in plant engineering.

Learn more

Conveyor Technology & Extraction Systems

In conveyor technology, hoses are used to efficiently transport materials, liquids or gases within systems. Extraction systems use hoses to safely remove exhaust gases, dust and other contaminants from machines and work areas. Both applications are crucial for smooth and safe operation in mechanical and plant engineering.

Learn moreOptimal Solutions for Machinery & Plant Engineering

Both systems – hydraulics and pneumatics – are central to efficiency and functionality in machinery and plant engineering. They enable precise control and automation, increase productivity and reduce manual labour. Selecting the right hoses is crucial to ensuring the longevity and reliability of the systems. In hydraulic systems, pressure resistance and tightness are particularly important, while flexibility and weight play a greater role in pneumatic systems.

Hydraulic systems are indispensable in many industrial applications because they can generate enormous forces. Hoses in these systems transport hydraulic fluids under high pressure from the pump to the actuators and motors that control mechanical movements. The precision and efficiency of the movements are determined by the quality and resilience of the hydraulic hoses, which must withstand extreme pressures and temperature fluctuations. They often consist of several layers, including an inner layer, a reinforcement layer made of steel braiding or textile fabric, and a protective outer layer.

Pneumatic systems, on the other hand, use compressed air to transfer energy. Hoses in these systems must be flexible yet robust to ensure fast and reliable control of machine drives and valves. These hoses are often made of materials such as polyurethane, polyethylene or PVC, which are lightweight and resistant to abrasion and chemicals. Pneumatic systems are particularly suitable for applications that require fast and frequent movements, such as in automation technology and robotics.

Accessories & Connection Parts

We not only offer the right hose for your needs, but also an extensive range of accessories that complement your hose system efficiently and reliably. From prefabricated solutions such as water hose fittings to custom-made components for your specific requirements: with APD Schlauchtechnik GmbH, you receive a technically flawless and well-designed product with all the necessary accessories for your application, from start to finish.